Interesting facts about construction of Kegums Hydro Power Plant

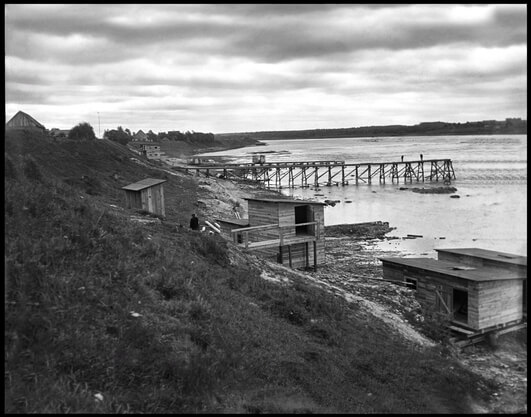

Initial work on the power plant building site

The work on the building site of the future power plant was started the next day after declaring the Law on Kegums Power Plant Construction.

"We may consider 5 August to be the day of commencement of the construction work, as this is when the initial pegging out and surveying work on the right bank of the Daugava River at Kegums was carried out,but the surveying of the building site was completed on 2 September." Ēvalds Šics, a technician of the construction inspectorate of Kegums Power Plant, wrote. The diary which was kept by order of the construction inspectorate of the power plant in now stored in the Latvian State Historical Archive − Diary of Kegums Power Plant Construction Work in 5 volumes (LSHA, f. 7319, inventory 8, file 72 – 76).

Temporary bridge over the Daugava River

It was important to ensure traffic between the two riverbanks for the construction to take place, so a temporary bridge was built first. The axis of the temporary bridge was pegged out 6 m downstream of the planned power plant dike, and the height of the bridge was 21 m above the Baltic Sea level. The temporary bridge was built from wooden structures. It was fitted with railway tracks to transport construction materials with trolleys.

"Around 80 workers are already working on the preparation of Kegums Power Plant construction site. In order to build the concrete piers of the permanent bridge before the ice is formed, the workers are accelerating the construction of the temporary wooden bridge. The wooden bridge spans across the Daugava River and will serve for the supply of materials for bridge piers and the construction of the steel bridge," the newspaper Tēvijas Sargs wrote on 18 September 1936.

Drilling work on the power plant building site

The choice of the power plant building site was determined by a more than 20 m thick layer of hard dolomite and water-tight clayey dolomitic marlstones in the Daugava riverbed, which was capable of withstanding the force of the pressure created by the dam, the power plant building and the mass of the water stored in the reservoir. The upper dolomite layer with a thickness of about 10 m on the riverbanks and 6 – 8 m in the riverbed was characterised by cracks and small voids. Significant efforts were made to strengthen the riverbed in order to prevent permeation of water, and this work was carried out using the special technology: the cement slurry injection. "9 m deep openings are being drilled at a distance of 1.5 m from each other, where the dolomite layer cracks and voids are filled with cement slurry with a pressure of 4 – 7 atmospheres." The drilling work was carried out continuously, working in 3 shifts. (Diary of the Power Plant Construction)

Divers

Well-trained divers worked on the power plant construction along with other qualified specialists.

"The temporary dam was so long that all divers had enough work to do. The flow of the Daugava River caused more and more leaks, and Mr. Hollberg, a Swedish engineer, threatened to summon divers from Sweden if the Latvians did not manage. I told my teammates that I needed a long bar, wooden wedges, empty bags and sawdust. At first, my mates mocked, but then they quietened down, as the water stopped coming through the dam. It was safer to "feed" the leaks up with debris that swelled in water rather than with ashes, slag, clay or sand, which would be sooner or later washed out by the water." (Memories of the diver Valentīns Pāvuls)

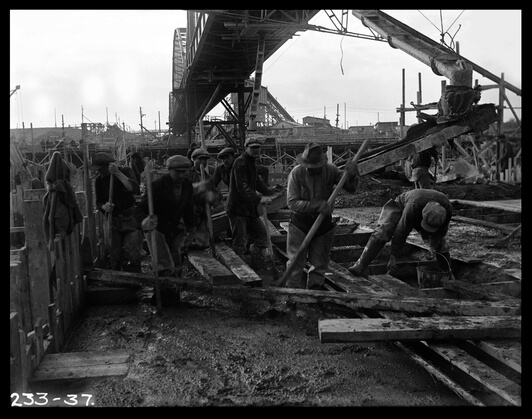

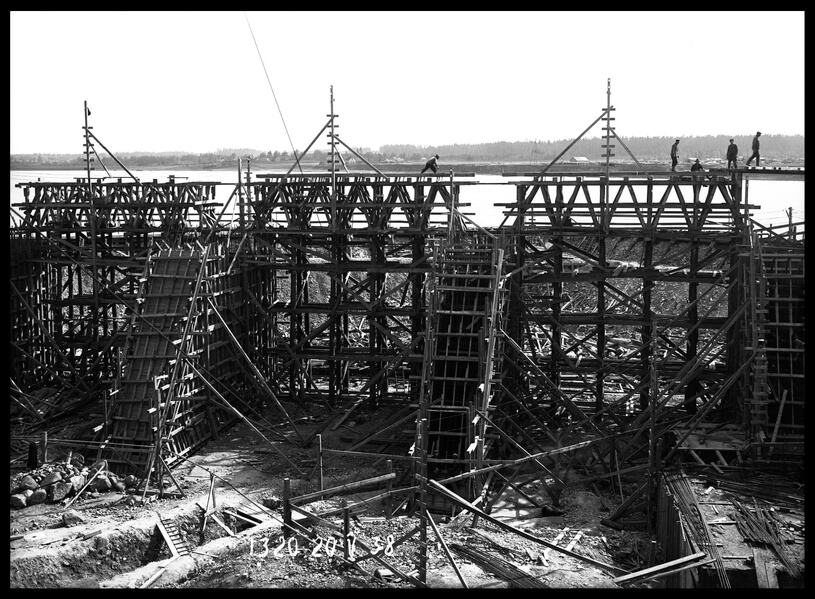

On the construction site

Temporary protective dikes were built for setting up the power plant construction site in the Daugava River. Dolomite was drilled with pneumatic drills to deepen the excavation pit. An excavator and workers loaded the crushed dolomite on the trolleys with shovels, and "little trains consisting of 4 to 6 trolleys carried it for filling the protective dike of the excavation pit. The 180 trolleys of rocks removed and filled in the protective dike during the evening shift from 2 pm to 10 pm was a record so far." (Diary of the Power Plant Construction)

Electricity supply

The electricity needed for the construction work was supplied by Jugla Electricity Company. A power line on the right bank of the Daugava River was built from the nearby high-voltage power line to Kegums, and a transformer was installed. Electricity provided lighting for the construction site, the workshops, the construction inspectorate office of the power plant and the workers' living quarters. A specially built power line over the Daugava River was also used to supply electricity to a sawmill located on the left bank of the Daugava River.

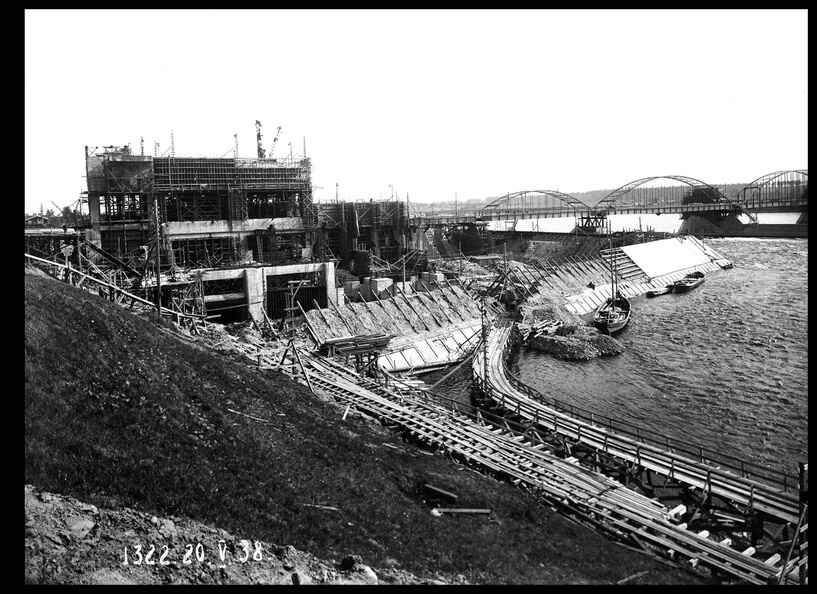

Construction of the permanent bridge

In the summer of 1937, a 500-metre long bridge made of interconnected metal sections was built on permanent piers. The bridge sections were mounted on the piers from both banks of the Daugava River using hoist rope fitted on steel structures (pylons), hoist winches and hydraulic jacks. To ensure the load-bearing capacity of the bridge, steel vaults were built. Railway tracks were installed on the bridge. Initially, the bridge was at a lower level because the construction of the dam and the power plant was carried out from it. During the construction of the bridge, a bridge suspended on steel cables was built for workers between the piers. 100 Latvian workers were engaged in the construction of the permanent bridge.

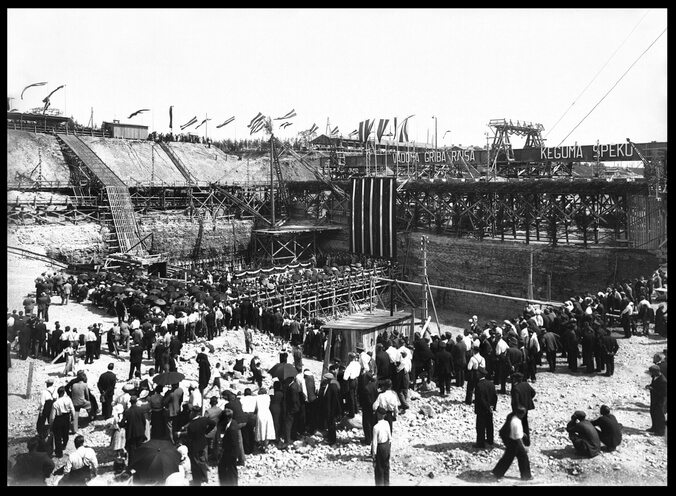

Foundation stone laying ceremony

On Saturday, 22 May 1937 "only morning shifts are working until 10 am. The building site is being decorated: the roads are being marked with birch branches, flags are being hoisted on flagpoles and the gate of honour is being adorned," reads a record in the Diary of the Power Plant Construction.

The foundation stone of Kegums Power Plant and a silver capsule with the Message for Future Generations were officially laid in the presence of President of Latvia Kārlis Ulmanis, government ministers, diplomats, representatives of local government institutions, academics of the University of Latvia, designers, contractors and builders.

Minister for Finance Ludvigs Ēķis said the following at the Kegums foundation stone laying ceremony:

"Today, we lay the foundation for the first Daugava power plant, a building that surpasses all the structures ever seen on this land in terms of its magnitude. Kegums Power Plant is an important technical event even on a European scale and in one sense or another it will be a European record. Kegums Power Plant will be able to introduce a new era in this country." (Latvijas Kareivis, 23 May 1937)

Workers in the construction of the power plant

The construction of the power plant attracted many hundreds and even thousands of workers. The contract of the Government of Latvia with the Swedish company Sentab laid down that "all administrative and technical staff of the power plant, as well as other employees and workers shall be manned by citizens of Latvia". Job-seekers from different places in Latvia arrived at Kegums: "Those who came by train from Latgale settlements crowded together on the station opposite the post office, with their belongings stacked in wooden boxes or handmade wooden trunks. Everyone had tools with them – axes, spades and saws. They were waiting in so long queues to apply for work at the power plant." (Memories of Alīda Miķelsone, the head of Kegums post office).

The most intense work on the construction site was carried out in 1938, when "people worked in 3 shifts of 8 hours constructing the turbine building on the right bank. On the left bank and in other places, they worked in 2 shifts of 10 hours with a night break from midnight to 4 am." On 15 December 1938, as many as 2,414 workers in total carried out the construction work. (Diary of the Power Plant Construction)

Official delegations and excursionists

The first group of interested people arrived at the building site as early as on 28 November 1936: they were 130 students of the Faculty of Engineering of the University of Latvia led by the building inspector Mārtiņš Robs.

Delegations of ministers of the Latvian government, representatives of state and local government institutions, Latvian and Swedish engineers, as well as engineers from Australia and other countries came to see Kegums. The interest in the construction of Kegums was great. Even tourist trains travelled to Kegums. For example, on 22 May 1938, the power plant building site was visited by 14 excursions with 800 participants. The biggest influx of those interested was on weekends: from 500 to 1,500 people per day. During the guided tours, they mainly saw the power plant building site on the right bank of the Daugava River.

"The majority of excursionists were schoolchildren and representatives of various organisations. Groups and organisations of engineers and technicians had the chance to have a closer look at the structure." (Diary of the Power Plant Construction)

Concrete batching for Kegums Power Plant

A concrete batch plant was built on the left bank of the Daugava River, in which three concrete mixers with a capacity of 1.25 m3 operated, each outputting 250 m3 of mixed concrete in 24 hours.

"Narrow-gauge trains run one after another from Birzgale on the left bank of the Daugava River to Kegums. They bring a hefty number of pebbles and gravel for concrete batching. At least 220,000 tons of concrete batch are required for the construction of the entire power plant. A train loaded with such quantity would stretch from Riga to Valmiera. Over 4,000 carloads of cement and many hundreds carloads of iron and steel will be consumed in Kegums."

(Atpūta, 5 November 1937)

"Everything has changed beyond recognition. Electric drills drown out shepherds' songs, while the monotonous squeaking of raft levers, which used to seem so loud in the past, can no longer be heard because of the powerful echo of hammering and the continuous rumbling of the trolleys. Kegums neighbourhood is now bustling with activity. A technical miracle – Kegums Power Plant – is emerging in the place of the quiet idyllic countryside."

(Atpūta, 5 November 1937)

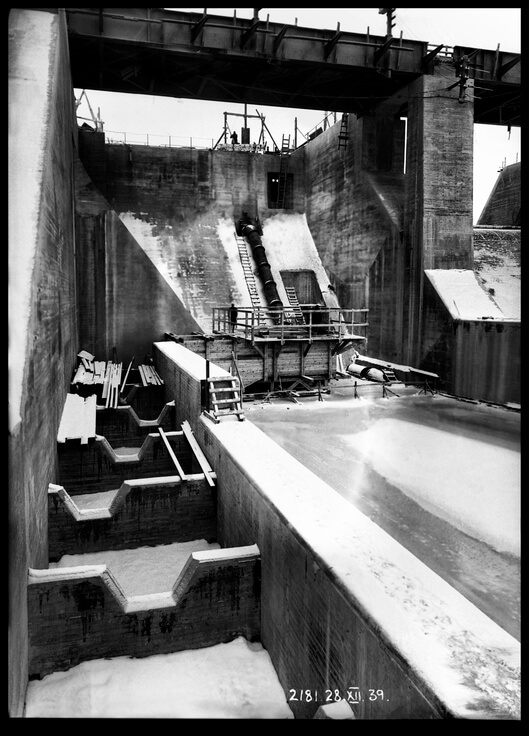

Concreting

Concreting was the most labour intensive process and the most physically hard work in the construction of the power plant. During the construction, more than a million cubic metres of ground and coarse-grained rock debris was shifted and about 235 thousand m3 of concrete was embedded in addition to using 79,200 tons of cement and 22 thousand tons of iron and steel. Although there were various construction aids deployed, mostly hand labour was used. Before concreting, dust, debris and mud were removed from the excavation pit walls. Concrete was batched in the concrete batch plant and delivered to the building site by trolleys. Then the concrete was poured through funnels or hatches built into the bridge into swivelling chutes, which channelled the concrete to the necessary sections.

Workers cast the concrete poured in the concrete structure formworks between metal reinforcing bars using shovels and wooden kneaders or kneading it with their feet, filling all spaces and gaps. Washed rough pebbles and stones were also immersed in concrete.

Concreting during the power plant construction was carried out throughout the year: both in winter and summer, day and night. The concrete batching technology and the concreting process differed between summer and winter. In the cold season, the necessary gravel and pebble mass as well as water were heated to prepare the concrete. The prepared concrete was covered with tarpaulins and heated with special ovens.

235,000 m3 of concrete

79,200 tons of cement

22,000 of iron and steel

Ice barrier

To protect the water inflow zone of the power plant from frazil ice in winter and drift ice in spring, an ice barrier was constructed. The ice barrier created an enclosed water pool. The ice barrier was a reinforced concrete structure on the supports embedded in concrete in the dolomite of the riverbed.

Describing this structure, engineer Pēteris Stakle noted: "This barrier will consist of 5-metre high and 2-metre thick reinforced concrete plate on equally solid supports. 3 metres of the wall will be in the water and 2 metres above the water. The floating ice will slide along the plate and will be carried away across the backside of the dam."

(Diary of the Power Plant Construction)

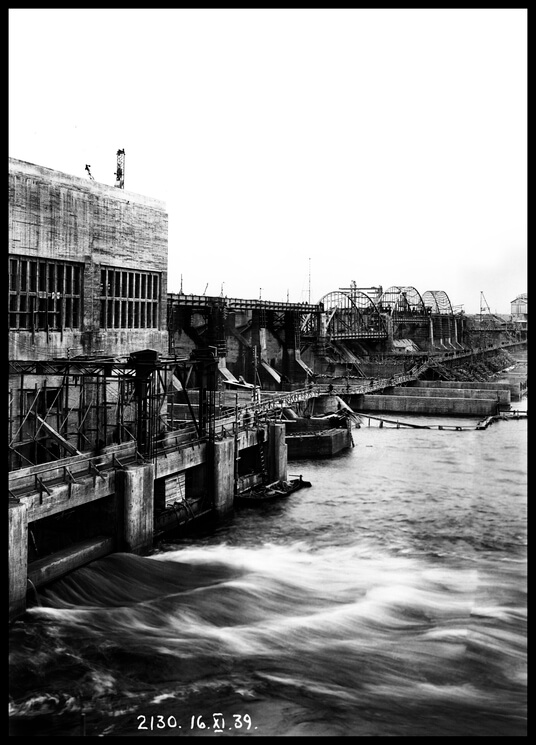

Power plant building

The power plant building was erected on the right bank of the Daugava River in order for the turbines to have inflow of water directly from the water reservoir. The power plant building has a length of 72 m. Its foundation is embedded in a dolomite layer in an excavation pit at a depth of 10 m. The whole building was designed as a monolithic reinforced concrete structure. The turbine suction pipes, turbine scrolls and the machine hall were constructed over the concrete pavement of the foundation. The roof thickness of the building reaches 2 m.

"When concreting the roof plate in the roof section of the building, concrete is being embedded in the thick steel reinforcement using wooden kneaders. There are 50 people working on the roof. 276.3 cubic metres of concrete have been cast here." (Diary of the Power Plant Construction)

Suction tubes were designed at a straight angle and coated with special clinker bricks for better resistance to water currents.

Administrative rooms, power plant control rooms and an electrical engineering laboratory were set up in a separate part of the building.

A pot of coins found

On 9 November 1938, a deposit of approximately one kilogramme of silver money – 879 coins wrapped in birch bark – was found when dredging the sand near Tuntuļi houses. The deposit dates back to the reign of the Swedish King Gustav Adolf in the first half of the 17th century. The deposit was transferred to the State Historical Museum (now the National History Museum of Latvia).

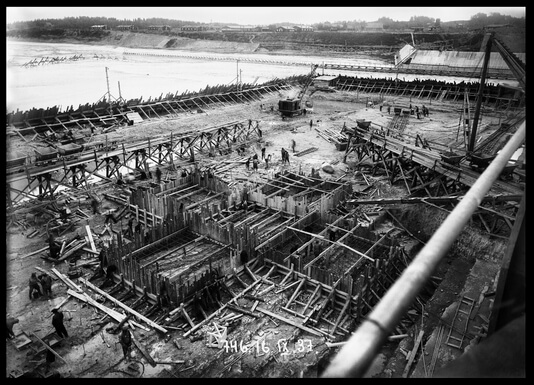

Power plant dam

The part of the construction work that required most responsibility was the preparation of the foundation for the Daugava River dam and the power plant building. The riverbed with temporary dams was narrowed by two thirds, setting up construction sites on the riverbed with an area of 3 ha. Workers' hands built a secure foundation for large structures here.

A solid 437 m long concrete dike was built on the foundation of the dam, and it was linked directly to the hard dolomite layer in the riverbed, removing only a 1 to 2 m thick chipped top layer. The width of the concrete dike is 5 m at the top and 20 m at the bottom. The main task of the dam is to maintain the backwater of the water reservoir. At the same time, the dam supports the bridge, gates and their operating systems. The height of the solid concrete dike in the gate apertures is 9 to 12 m. A water spillway with 13 gates was built for water passage, and it was made of a steel frame, plated with steel sheets.

The riverbed of the Daugava River downstream the dam was strengthened with reinforced concrete floor with a thickness of about one metre.

437 m

length of concrete dike

9 – 12 m

height of the dikes

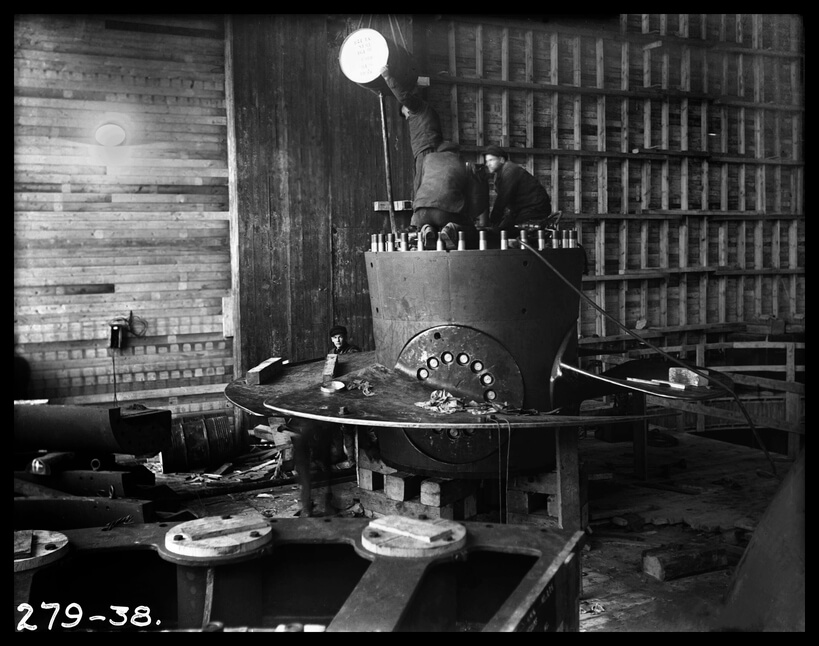

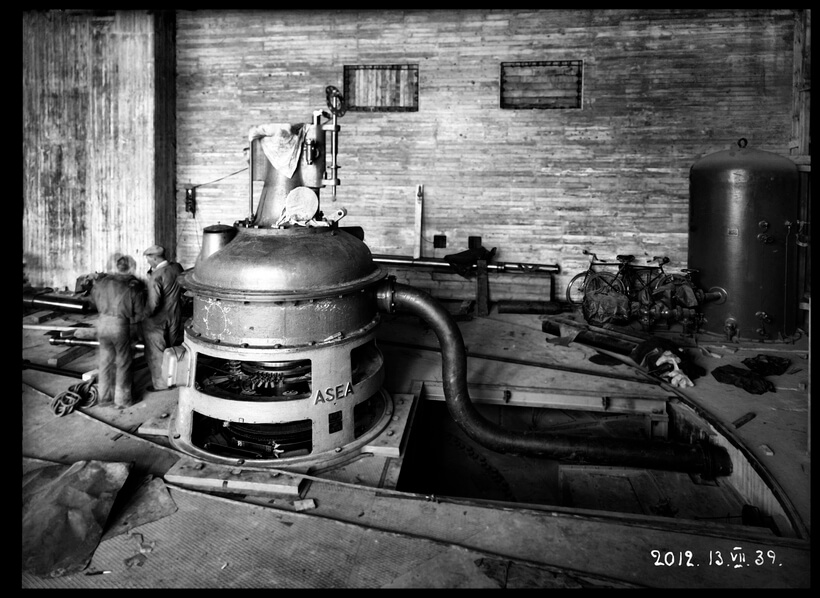

Assembly of the power plant equipment

The hydropower unit turbines and generators were manufactured at Swedish factories KMW and ASEA. On 25 November 1938, the equipment was delivered to Kegums: "KMW is delivering a turbine. The carriage enters the power station building by rail where the cargo is unloaded using a 170-ton crane." At the same time, the assembly of two turbines was started, along with preparation of the structures for installing two more turbines.

(Diary of the Power Plant Construction)

Machinery in the construction of the power plant

Various machinery and aids – a total of more than 300 different units – were used in the construction of the power plant. In 1936, one Universal-35 excavator and two Ruston-32 excavators were delivered for work on the power plant construction sites and Birzgale gravel mine. In 1938, the fourth excavator was delivered. There were 8 construction cranes, as well as engine pumps, compressors, ramming and drilling equipment and welding, cutting and other machinery engaged in the construction work. 14 diesel locomotives with 143 different types of trolleys were used to transport heavy loads. They ensured the transfer of gravel from Birzgale gravel quarry to the concrete batch plant and transportation of the excavated dolomite and building materials on the power plant construction site. Most trolleys used in the construction were manufactured at Vairogs factory in Riga. Tractors with special auxiliary equipment – rollers, levellers and carts – were used for heavy earthwork.

Rafting

The Daugava River had long been the biggest transport route for rafting and transportation of various materials by barges. During the power plant construction, rafting was carried out in the stream of the Daugava River which was not restricted by temporary protective dams. The route was narrow and required great precision to raft. Rafting became more and more complicated when the concrete dam was being built: "13 April 1937: rafts should be directed into the large stream in good time. It is not enough to have 8 men on a raft, as the stream is fast. 21 April 1938: an attempt is made to launch a raft between piers 7 and 8 above the gallery embedded in concrete and the foundation of the dam. The first raft goes without people and the other has a crew – it goes well." A supervisor was appointed to regulate the raft traffic.

(Diary of the Power Plant Construction)

Crane of the power plant machine hall

In order to start the assembly of equipment, a crane with a lifting capacity of 170/10 t was installed in the machine hall. The entry in the construction diary of 2 August 1938 reads that "the installation of the 170/10 ton portable crane and electric drives has been completed," and on 5 August, a test of the capacity of the crane was carried out: "Various iron materials with a total weight of up to 200 tons are delivered and loaded in the machine hall. A load of 198.89 tons is applied (in the big hook), holding it up for 7 minutes." The crane was used for moving heavy parts of the equipment, for the assembly process and for repairs of the equipment at a later time.

The power plant turbine

is a Kaplan type turbine with four turning blades, manufactured by KMW (Sweden) in 1938.

Turbine technical parameters:

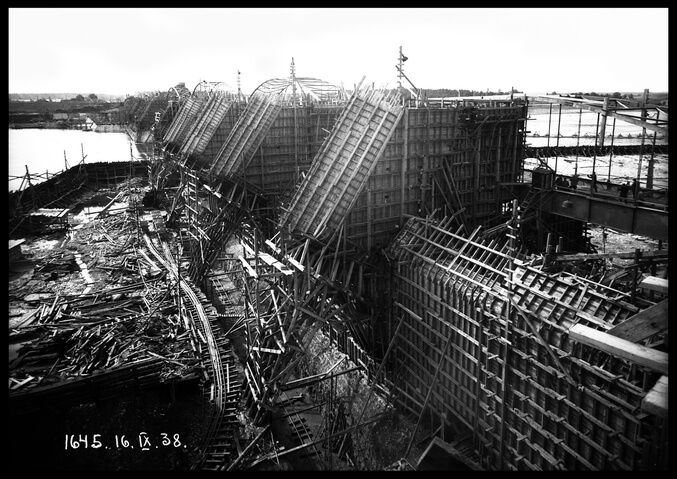

Flood

During the construction of the power plant, the water of the Daugava River caused quite a few problems to the builders. The river never got frozen evenly. Ice-holes remained in stepped sections, which contributed to the formation of frazil ice in autumn and ice jamming and clogging in spring. The entry made in the diary of Kegums Power Plant construction on 9 February 1939 reads that the construction works are carried out under the threat of ice drift, as the ice in the Daugava River has clogged and stopped from the mouth of the Aiviekste River to Jaunjelgava (located about 30 kilometres upstream the power plant building site). On the morning of 10 February, ice drift started at Kegums: "Breaking the ice on the front of the dam, it goes down in big masses. The protective dikes are unable to withstand the water pressure. They collapse. The river claims back all the building sites gained from the Daugava River. Only concrete structures are holding tight." (Diary of the Power Plant Construction)

In the words of "Jaunākās Ziņas": "The disaster with dams begins at 12:45 pm. At 12:55 pm, the walls are already broken and both construction sites are filled with water and ice. The Daugava River unleashed at least 100,000 cubic metres of water on the construction sites within 10 minutes, the amount equal to that contained in a fairly large lake."

Power plant water reservoir

In September 1939, the increase of the water level in the reservoir gradually began: "The increase of the water level in Lake Kegums is going on slowly, as the small flow rate in the Daugava River (about 67 m3/s) allows the use of only about 20 m3/s for damming, while the rest is passed through the 1st turbine pit, so that the bottom of the Daugava River is not left completely dry."

(Diary of the Power Plant Construction)

The increase of the water level in the reservoir continued throughout October into early November, and the water reservoir reached the design height of 32.0 m above sea level in June 1940.

The width of the filled Daugava River at Kegums reaches about 1,500 m, creating a 15.75 m high head. The water reservoir is 40 to 50 km long with an average depth of 7 to 10 m. The water reservoir plays an important role in the operation of the power plant as it ensures the control of the Daugava River water flow, using the water accumulated overnight in the daytime when the consumption of electricity is higher.

40 – 50 km

length of water reservoir

7 – 10 m

depth of water reservoir

Assembly of generators

The pace of work was high, as the first two generators had to be ready for start-up in a few months. The assembly work was not easy: "14 March: ASEA assembles the generator rotor. The upper iron ring is heated up by flame lamps to a temperature of about 300 °C, and as the diameter increases, the ring is put on the rotor star."

Three rings were mounted in this way on the rotor star of each generator.

(Diary of the Power Plant Construction)

88 kV high-voltage substation and power lines

In order to provide the supply of the electricity generated at the power plant to customers in cities and rural areas, a high-voltage substation was built in Kegums and the first 88 kV double-circuit power line to Riga was constructed.

"On 18 March, the first iron tower for Riga lines is built. On 13 October, a distant cable line to Riga is tested by turning on the power to Riga transformer station. The voltage is gradually raised." The first power line Kegums – Riga was 42 km long and it was built using 800 poles. Steel poles were used in the 2 km section at Kegums and in the 1 km section at Janciems substation, Riga, while wooden poles were used in the remaining sections.

Latvia will have light!

On 15 October 1939, the first hydropower unit of the power plant was started up and the high-voltage power line Kegums – Riga was switched on: "At 11:45 pm we succeeded in connecting Kegums power through Riga transformer station to Riga network. Kegums outputs about 4,000 kW."

(Diary of the Power Plant Construction)

On 17 November, the second hydropower unit was started up and on 18 November, Riga began to receive a permanent supply of electricity generated at Kegums: "The energy produced by the "white coal" – the mighty stream of the Daugava River – started to flow yesterday."

("Jaunākās Ziņas", 19 November 1939)

In December, the power from Kegums was transmitted to Jelgava, Bauska, Dobele and other cities of Latvia, but on 8 February 1940, the power line Kegums – Ieriki was launched.

Fish-pass

The lower reaches of the Daugava River have always played a major role in the fishing industry. In order not to cause serious damage to the ecology of the Daugava River, the design of the power plant provided for constructing a fish-pass at the dam. A chamber fish-pass was installed for fish migration, ensuring easy and convenient movement of fish across the dam. The fish-pass was built of 86 chambers, each 3x3 m wide and 1.5 – 1.7 m deep. They were placed one after another, with a difference of 20 cm between height levels, estimating that migrating fish – the salmon would move by jumping from one chamber to the other, while the eel would move by getting through the opening left in the walls. The water flow in the fish-pass chambers was 0.6 m3/s. Engineer Pēteris Stakle, construction inspector's assistant, noted: "Such fish-passes have proved useful in Canada, Sweden and other northern countries."

The fish-pass was tested upon the completion of its construction in the summer of 1940. An entry in the construction diary points out: "By filling the lower reach camera through an 800 mm tube and running water through the row of the steps, a wealth of fish can be seen going up this live stream. A specialist from Tome fish farm is participating in the test." Fish farmers considered this type of structure to be one of the most effective.

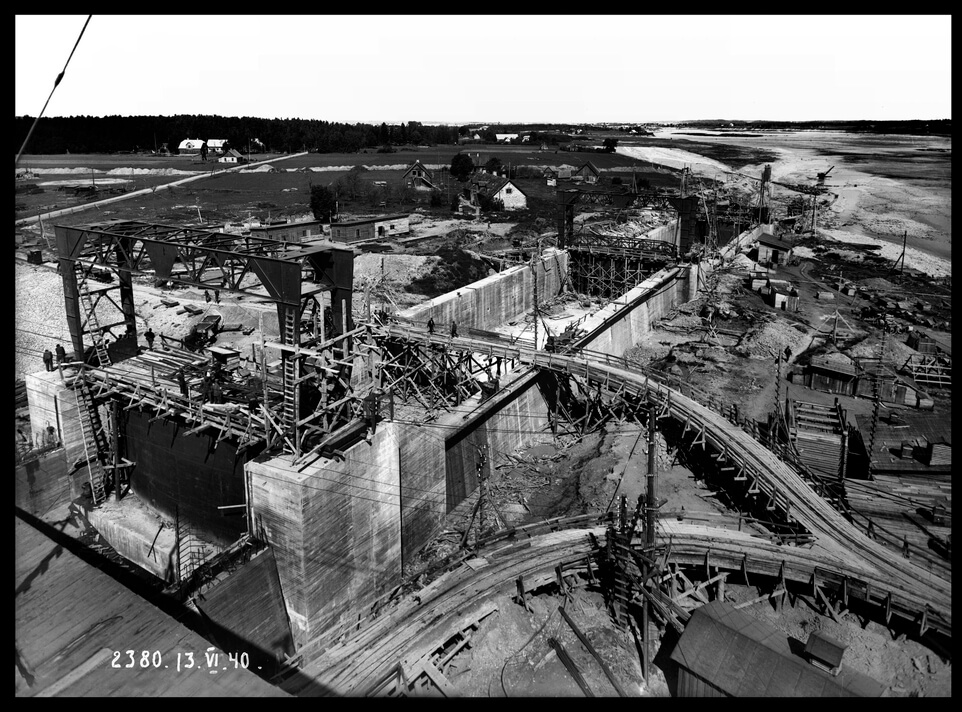

Earth dikes of the water reservoir

High dikes adjoining the power plant dam were built on both the right and the left bank of the Daugava River. They were made of clay, gravel and sand. The sand brought by a tractor was first levelled on the dike wall, then compacted and watered. A clay deck was embedded in front of the dike, while large boulders brought by local farmers with horse-drawn carts were used to reinforce the surface.

The width of the earth dikes is 8.5 m at the top and the length is about 200 m on the right bank and more than 1 km on the left bank. The earth dikes were also planned to be used for road traffic, building a highway.

Construction of the rafting canal

A rafting canal was built for the traffic of rafts and barges. Describing this engineering structure, engineer

P.Stakle emphasised that "the shipping lock step was designed from four 17-metre wide, 80-metre long and 1.7-metre deep chambers, located approximately 4 metres below each other. Estimates show that 150 rafts can pass through these locks in 24 hours, consuming no more than 10 cubic metres of water per second." A unique remote control system was built to control the rafting canal.

The newspaper Brīvā Zeme wrote in 1939: "Rafts and boats will pass through the lock canal on the left bank of the Daugava River. There will be a new riverbed of the Daugava. In the future, the boats will go where the Daugava barge haulers used to trample the banks of the Daugava River." The efficiency of the rafting canal structure was later demonstrated also by its capability to run a 70-metre long raft through the lock system in a very short time – 15 minutes.

Kegums – our great achievement!

The power plant was built as a result of persistent work of three and a half years. Assessing the construction of Kegums Power Plant, both European and Latvian engineering experts acknowledged that "this test of Latvian entrepreneurship and capability was passed well. The electric energy generated by the Daugava water serves people's well-being in the form of light, power and heat".

(Ekonomists, 1 February 1940, Pašvaldību darbinieks, 1 October 1939)